Fermenter

Laboratory fermenter operation principle——Regulation of TEMP

Time:2023.02.04

Influence of laboratory fermenter temperature

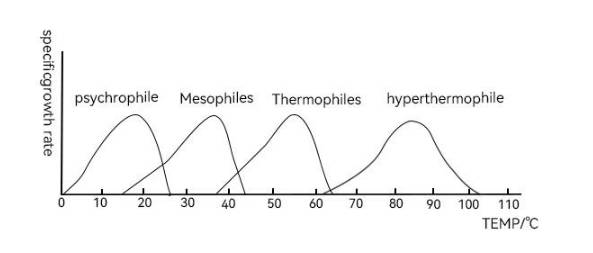

The temperature of the fermenter affects several parts of the fermentation process, such as affecting the reaction rate of enzymes, changing the direction of synthesis of bacterial metabolites, affecting the metabolism of microorganisms, etc.

Too high a temperature will accelerate the metabolism and aging of the strain, or even kill the strain directly; too low a temperature will slow down the metabolism of the bacterium and reduce the rate of product synthesis, thus affecting production.Some strains change their metabolic pathways at different temperatures, and the corresponding products will vary.

Too high a temperature will accelerate the metabolism and aging of the strain, or even kill the strain directly; too low a temperature will slow down the metabolism of the bacterium and reduce the rate of product synthesis, thus affecting production.Some strains change their metabolic pathways at different temperatures, and the corresponding products will vary.

The optimum fermentation temperature of the fermenter is not only beneficial to the growth of bacteria, but also to the synthesis of metabolites.However, the optimum temperature of the same microorganism requires different conditions in different cultures. Therefore, how to maintain the normal and stable temperature of the laboratory fermenter is an important part of the fermentation process.

How to adjust the TEMP of laboratory fermenter

The laboratory fermenter is mainly used to regulate the fermentation temperature in real time by positive and negative temperature.As an example,the HOLVES laboratory glass fermenter is equipped with a 24V low voltage safety electric blanket and cooling pipe module.

The user sets the parameters of the heating and cooling process via the HF-Control control software of HOLVES. The temperature electrode collects the temperature from the fermenter and then, via the integrated control module, converts the collected analog signal into a corresponding value to be sent to the PLC for comparison with the originally set temperature value.

After PID calculation, if the current value is detected to be higher than the set value, the heat source of electric blanket will be closed and the solenoid valve of cooling water will be opened to reduce the temperature of fermenter; if it is lower than the set value, the solenoid valve of cooling water will be closed and the electric blanket will be opened.

In addition, the optimal fermentation temperature is divided into optimal growth temperature and optimal production temperature, which are not necessarily the same and need to be distinguished in the fermentation process.

By the way, in order to disperse the gas-liquid contact and speed up the reaction in fermentation, the laboratory fermenter will also be controlled by stirring. The next article will explain in detail.

By the way, in order to disperse the gas-liquid contact and speed up the reaction in fermentation, the laboratory fermenter will also be controlled by stirring. The next article will explain in detail.